Introduction

Rubber bearing sleeves are small but essential parts found in vehicles, industrial machines, and power systems. They absorb vibration, reduce friction, and protect shafts and bearings from wear. Without them, equipment would be louder, less reliable, and more expensive to maintain. This guide covers everything you need to know about rubber bearing sleeves: their structure, materials, properties, applications, and how to choose the right type.

What Is a Rubber Bearing Sleeve

A rubber bearing sleeve is a cylindrical or flanged part that sits between a shaft and its housing or bearing. Its purpose is to act as a cushion, reducing direct metal-to-metal contact. By doing this, it lowers vibration and noise while extending the service life of the system.

Think of it like the sole of a shoe. It softens each step, reducing stress on your body. A rubber sleeve works in the same way for machines, reducing stress on moving components.

Structure and Design Features

Rubber sleeves come in different forms depending on the application:

- Straight sleeves: simple hollow cylinders used in general machinery.

- Flanged sleeves: include a rim to prevent axial movement.

- Grooved sleeves: with channels to help distribute lubricant and reduce heat.

- Reinforced sleeves: combine rubber with metal or fabric for higher strength.

Each design solves a specific engineering challenge. For example, grooved sleeves in pumps improve lubrication and cooling, which prevents premature wear.

Materials Used in Rubber Bearing Sleeves

The performance of a sleeve depends on its rubber compound. Common materials include:

- Natural Rubber (NR): flexible and elastic, used in light-duty applications.

- Nitrile Rubber (NBR): resistant to oil and fuel, popular in automotive and hydraulics.

- EPDM: durable against heat, ozone, and weathering, used outdoors and in cooling systems.

- Neoprene: balanced resistance to oil and weather, suitable for many industries.

- Silicone Rubber: stable at high temperatures, often used in aerospace or food-grade systems.

- Viton (FKM): excellent chemical resistance for harsh industrial conditions.

Related articles : Rubber Bearing Sleeve Material Analysis: How to Choose the Right Compound

Case Example

A factory using conveyors in a food processing line once installed NR sleeves. They failed quickly due to constant contact with oils. After switching to NBR sleeves, replacement intervals doubled, reducing both downtime and costs.

Key Properties and Performance

A high-quality rubber bearing sleeve should demonstrate:

- Wear resistance for long-term use.

- Low friction to minimize energy loss.

- Ability to recover shape after compression.

- Strong vibration and noise absorption.

- Stable performance under low and high temperatures.

- Resistance to oils, water, and some chemicals.

Real-World Scenario

A city bus engine fitted with rubber sleeves runs smoother and quieter. Without them, passengers would feel strong vibrations at every stop and start.

Manufacturing Process

The production of rubber bearing sleeves follows several stages:

- Mixing raw rubber with additives for strength, elasticity, and resistance.

- Shaping by extrusion or molding into the required form.

- Vulcanization under heat and pressure to lock in performance.

- Finishing processes like trimming or bonding with a metal shell.

- Quality control testing, including hardness (ASTM D2240), wear resistance (ISO 4649), and fatigue life.

Related articles : Rubber Bearing Sleeve Manufacturing Process: A Step-by-Step Guide

Applications of Rubber Bearing Sleeves

Rubber sleeves appear in many industries:

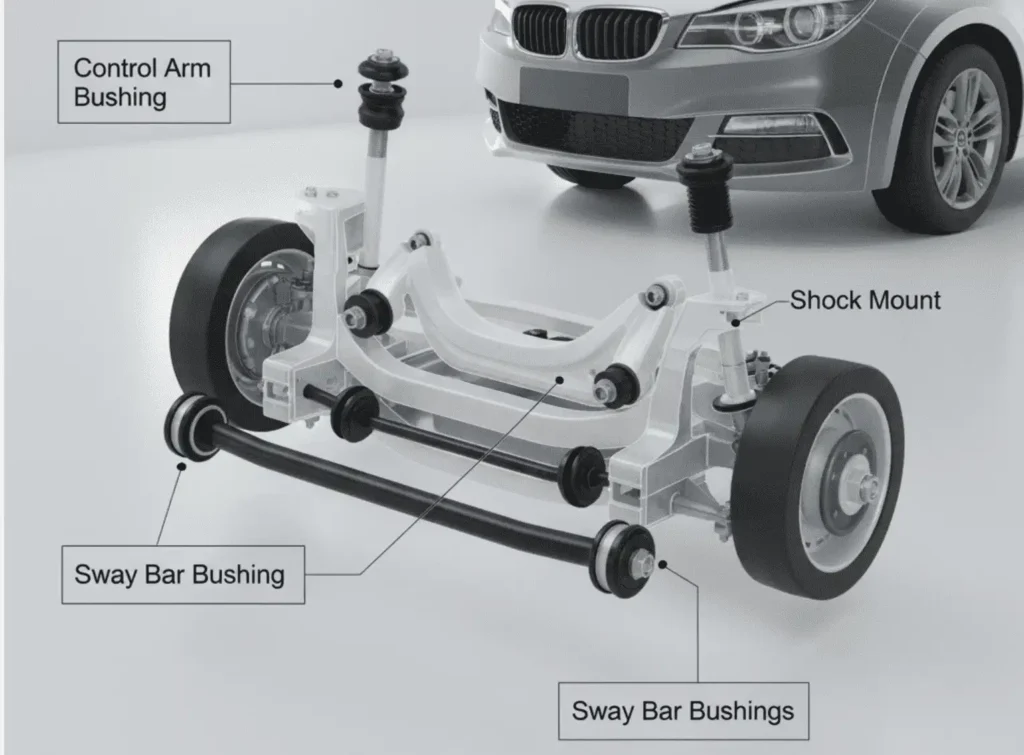

- Automotive: engine mounts, suspension systems, drive shafts.

- Industrial equipment: pumps, compressors, conveyors, fans.

- Aerospace and rail: vibration isolation in critical systems.

- Power generation: turbines, wind generators, and motors.

- Consumer appliances: refrigerators, washing machines, and HVAC units.

In each case, the sleeve reduces vibration and protects more expensive components.

Advantages of Rubber Bearing Sleeves

Rubber sleeves are widely used because they offer:

- Excellent vibration and noise reduction.

- Lower cost compared to metal or ceramic sleeves.

- Easy installation and replacement.

- Customization in size and compound.

- Reduced need for lubrication in some designs.

Limitations and Challenges

Rubber sleeves are not the best solution for every application. They have limits in load capacity and high-temperature performance. Aggressive chemicals may also damage them.

Case Example

A mining crusher operating at very high speeds used rubber sleeves but faced rapid failures. Switching to metal sleeves solved the problem because the load was too extreme for rubber to handle.

Comparing Rubber, Metal, and Plastic Sleeves

To make a better choice, it helps to compare materials:

- Rubber: Best for vibration absorption, noise reduction, and moderate loads.

- Metal: Best for high load and high-speed environments, but noisier.

- Plastic (Nylon, PTFE): Lightweight, corrosion-resistant, but less effective at absorbing vibration.

Each type has its place. In low- to medium-load systems, rubber often provides the best balance of cost, performance, and comfort.

How to Select the Right Sleeve

Choosing the right sleeve requires knowing your conditions. Key factors include:

- Load and speed: heavier loads may require reinforced rubber or metal alternatives.

- Temperature: confirm the rubber type can handle both cold starts and high heat.

- Environment: check for oil, water, or chemicals.

- Service life: balance cost with replacement frequency.

Buyer’s Tip

Always ask suppliers for material data sheets and certifications. For example, if your pump operates with diesel, ask for NBR with oil resistance, not general NR.

Maintenance and Troubleshooting

Rubber sleeves are consumables. Their life can be extended with proper care:

- Inspect regularly for cracks, hardening, or wear.

- Avoid using harsh chemicals during cleaning.

- Replace sleeves showing early signs of failure.

- Use compatible lubricants if lubrication is required.

Common issues include premature aging, loosening, or noise increase. Preventive replacement is often cheaper than emergency downtime.

Standards and Certifications

Quality rubber sleeves are tested against international standards. Some key ones include:

- ASTM D2240: hardness testing.

- ISO 4649: abrasion resistance.

- ASTM D395: compression set.

- ISO 37: tensile strength.

Checking for compliance with these standards ensures reliability.

Future Trends

Rubber bearing sleeves are evolving with new technology and sustainability demands.

- Advanced materials: high-performance elastomers for higher load and temperature.

- Eco-friendly compounds: recyclable and bio-based rubbers.

- Smart sleeves: embedded sensors for real-time monitoring of wear, vibration, and heat.

These innovations will make sleeves not just passive parts, but active contributors to predictive maintenance and sustainability goals.

Conclusion

Rubber bearing sleeves are simple but vital. They reduce vibration, cut noise, and extend machine life. With the right material and design, they can save money and improve reliability across industries.

By understanding their structure, properties, and limits, engineers and buyers can make better choices. With ongoing innovation in materials and smart technologies, rubber sleeves will continue to play a key role in future machinery.

If you’re looking for Rubber Bearing Sleeve, visit our Rubber Bearing Sleeve Manufacturer Page